Phone : +91-9827113763 | +91-7587733050

Venturi Scrubber

Quick Overview

We are An ISO-9001:2015 Certified Company & Air Pollution Control Equipment Venturi Scrubber Manufacturer in Delhi. An ejector or venturi scrubber is an industrial pollution control device, usually installed on the exhaust flue gas stacks of large furnaces, but may also be used on any number of other air exhaust systems. To this end, an ejector venturi scrubber (as well as the spray tower) uses a preformed spray, the difference is that only a single nozzle is used instead of many nozzles.

This nozzle operates at higher pressures and higher injection rates than those in most spray chambers. The high-pressure spray nozzle (up to 689 kPa or 100 psig) is aimed at the throat section of a venturi constriction.

The ejector venturi is unique among available scrubbing systems since it can move the process gas without the aid of a blower or fan. The liquid spray coming from the nozzle creates a partial vacuum in the side duct of the scrubber.

Product Description

Because of their open design and the fact that they do not require a fan, ejector venturis are capable of handling a wide range of corrosive and/or sticky particles. However, they are not very effective in removing submicrometer particles.

venturi Scrubber systems consist of the following components:

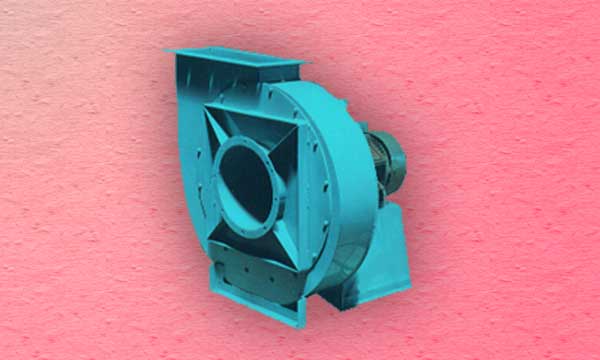

- Ductwork and fan system

- A saturation chamber (optional)

- Scrubbing vessel

- Entrainment separator or mist eliminator

- Pumping (and possible recycle system)

- Spent scrubbing liquid treatment and/or reuse system

- An exhaust stack

We Provided Complete System for following Industry

- Steel Induction Furnace

- Steel Re-rolling Mill Industry

- Sponge Iron Plant (DRI)

- Boiler (Heating process & Power Palnt)

- Lead Recycling Plant

- Aluminium Recycling Plant

- Copper Recycling Plant

- Dross Recycling Plant

- Slag Processing Unit

- Process Furnace

- Chemical Process Plant

- Casting Units

- Rice Mill Industry

- Wire (Binding) Industry

- Plywood Industry

- Paper Mill

- Lime Kiln

- Cement Kiln

- Textile Mill

- Fertilizer Plant

| To be Total Gas Volume in CFM | ********* CFM |

| Effective Height in meter | ********** m |

| Diameter in meter | ******* m |

| ID Fan | ******* Kw |

| Duct Size | ******** m |

| Water Pump Capacity | ******* Ltr/hr |